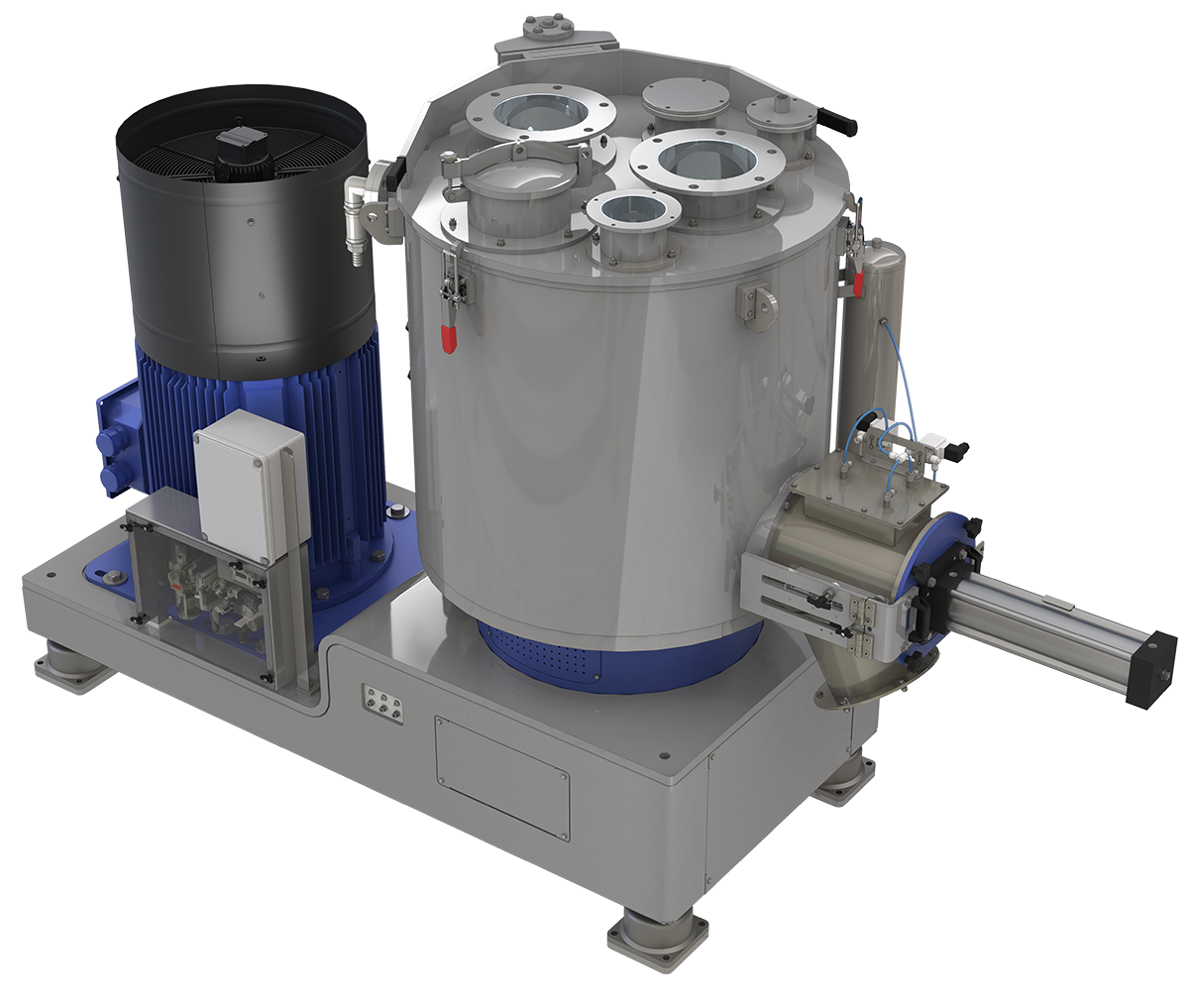

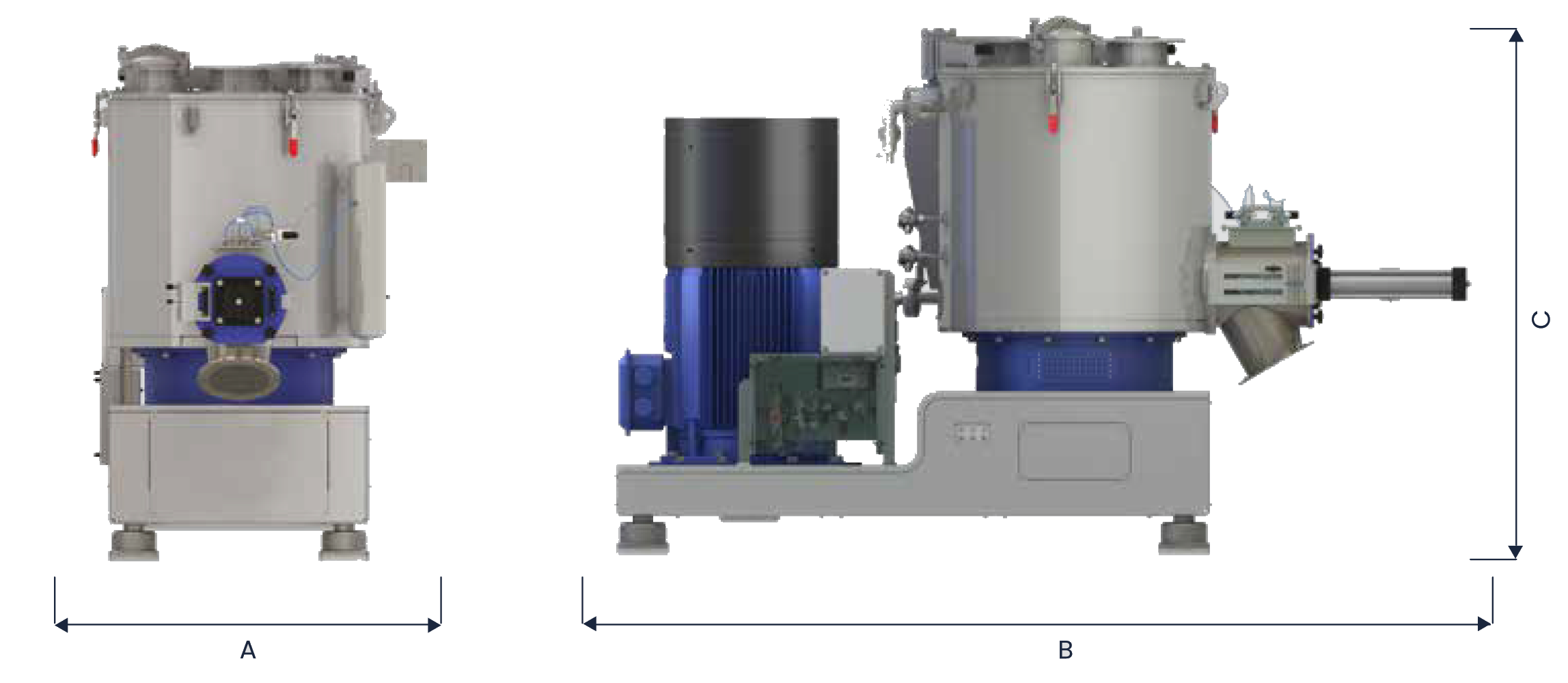

mixron MVB

High-Speed Turbo Mixer for Li-ion Battery Powder

High-Performance, efficiency

and technological innovation.

The mixron MVB mixer allows temperature-controlled mixing of Lithium Battery Powders.

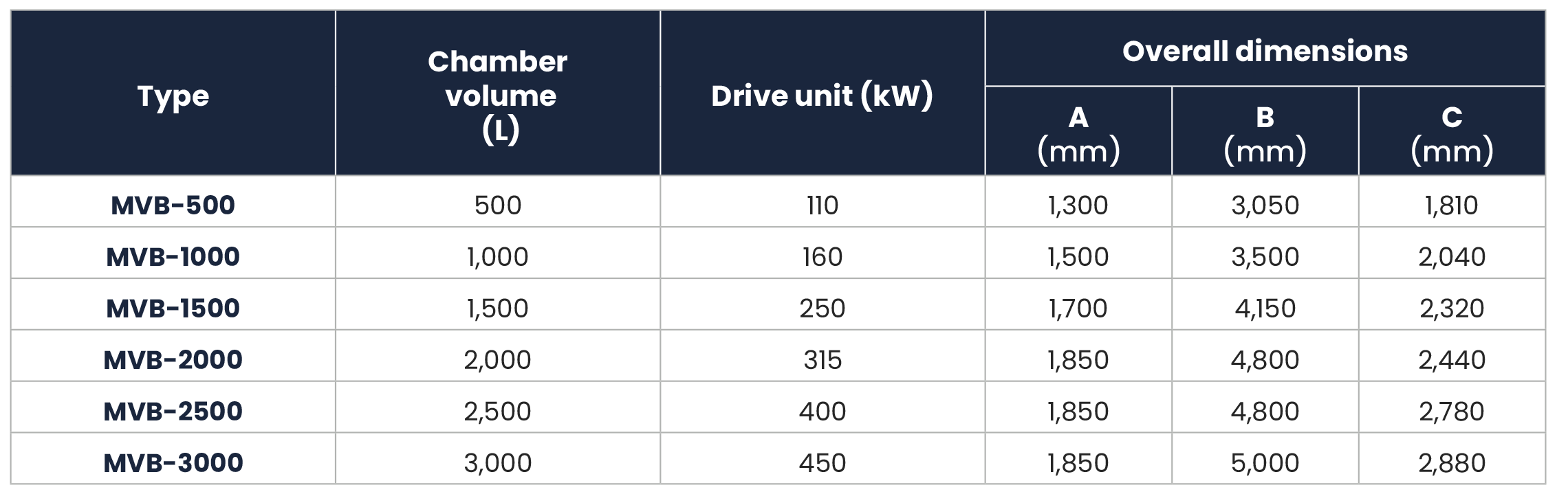

The range includes mixers from 500 to 3,000 litres, all made of stainless steel to avoid any possible contamination.

Discover the whole range

The goals we care about most…

Efficiency

Productivity

Asset durability

Flexibility

… and our solutions to achieve them

Mixing Vessel

All mixron MVB mixing vessels are completely coated to avoid any contact between the mixed material and metal surfacese:

- No possible contamination

- High-Resistance to abrasive materials

- One or more outlet available

- External liquid cooled jacket to avoid temperature increase

![]()

![]()

![]()

Mixing tools

Manufactured in a single seamless piece with variable thickness to ensure:

- Higher mixing efficiency

- Fully coated to ensure durability in continuous operations

![]()

![]()

![]()

Coatings

A large variety of coatings is available to protect and improve the parts in contact with mixed materials:

- Ceramic tiles

- WC HVOF

- Al2O3 APS

- Resin Ceramic

- Peek

- ETFE

![]()

![]()

![]()

Air Purged Cleaning System on discharge device

- Adjustable-double controlled air flow

- Keep clean the plug seal to avoid any leakage from the vessel during the mixing cycle

![]()

Hinged discharge device for easy cleaning & inspection

- Easy access to discharging device

- Fully openable

- Vessel plug completely accessible

- Safe and easy cleaning operations

![]()

![]()

![]()

Deflector

All mixron MVB mixers are equipped with a completely coated deflector to enhance vortex mixing:

- Replaceable with easy assembling

- Fully coated

- Improve mixing quality

- Reduce mixing time

![]()

![]()

![]()

Power transmission

Offers numerous advantages thanks to low-friction toothed belt and central lubrication:

- No slippage with maximum power transfer

- Less load on bearings

- Belt replacement in 3 simple steps without dismantling the bearings

- Lower frequency of belt tensioning

- Bearings replaceable without disassembly the vessel

- Compact overall dimensions facilitating replacement of existing mixer

- Quick maintenance providing higher mixing performance

![]()

![]()

![]()

![]()

All rights reserved – Mixron srl – Via Brigata Ebraica, 50 – 48123 – Ravenna (RA) – ITALY – P.IVA 03456680366