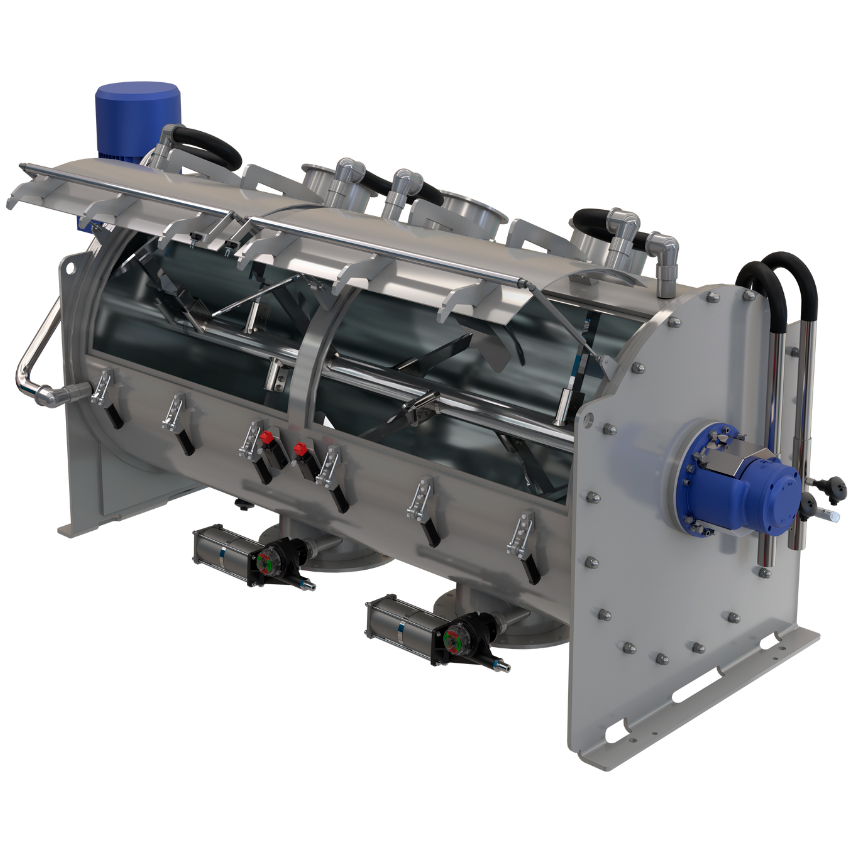

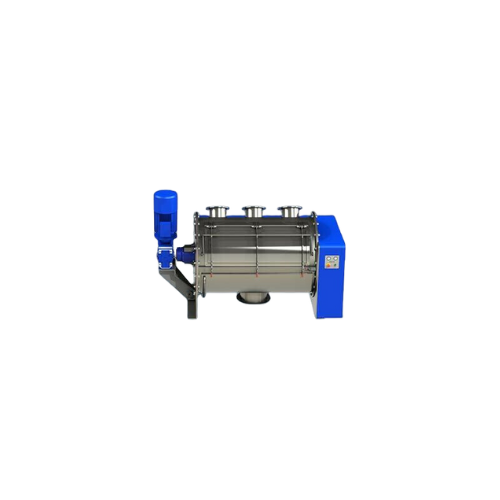

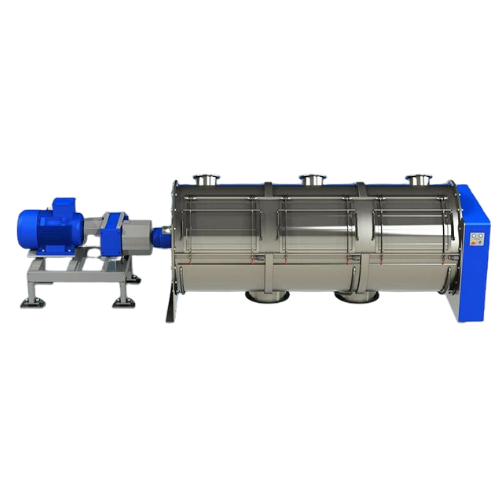

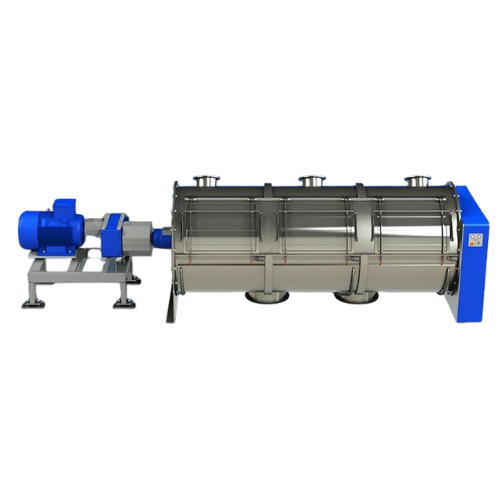

mixron MCP

Cooling Mixer for PVC Dry-Blend

Discover the whole range

Horizontal-shaft cooler, with

forced cooling liquid circulation

for both rigid and plasticised PVC Dry-Blend.

The cooling technology enables mixron MCP to lower the temperature of the product in an extremely short time while maintaining homogeneity and final quality of the mixture. The range including machines from 1,600 to 10,500 litres is entirely manufactured from stainless steel to ensure high resistance to oxidation and corrosion and to guarantee durability.

Find out how it works

MCP 1600

Construction: AISI 304

Nominal Capacity: 1600 lt

Installed Power: 11 kW

Max. Temperature: 130°C

Cooling liquid: H20 15°C

Dimensions: L2800 x P1365 x H1630

MCP 2000

Construction: AISI 304

Nominal Capacity: 2000 lt

Installed Power: 18,5 kW

Max. Temperature: 130°C

Cooling liquid: H20 15°C

Dimensions: L3030 x P1365 x H1710

MCP 3000

Construction: AISI 304

Nominal Capacity: 3000 lt

Installed Power: 30 kW

Max. Temperature: 130°C

Cooling liquid: H20 15°C

Dimensions: L4055 x P1365 x H1820

MCP 4800

Construction: AISI 304

Nominal Capacity: 4800 lt

Installed Power: 45 kW

Max. Temperature: 130°C

Cooling liquid: H20 15°C

Dimensions: L4700 x P1570 x H1945

MCP 6000

Construction: AISI 304

Nominal Capacity: 6000 lt

Installed Power: 55 kW

Max. Temperature: 130°C

Cooling liquid: H20 15°C

Dimensions: L6585 x P1670 x H1775

MCP 8800

Construction: AISI 304

Nominal Capacity: 8800 lt

Installed Power: 75 kW

Max. Temperature: 130°C

Cooling liquid: H20 15°C

Dimensions: L7150 x P1875 x H1975

MCP 10500

Construction: AISI 304

Nominal Capacity: 10500 lt

Installed Power: 75 kW

Max. Temperature: 130°C

Cooling liquid: H20 15°C

Dimensions: L8550 x P1975 x H2075

The goals we care about most…

Efficiency

Productivity

Asset durability

Flexibility

… and our solutions to achieve them

Inlet Spouts

Each type has at least 3 inlets as standard:

- Main loading spout

- Auxiliary loading spout

- Spigot for connection of a filter unit

![]()

Outlet Spouts

A pneumatically actuated flush chamber discharge spout is provided as standard:

- Obtaining optimum mixing quality

- Mixing and cooling all the material inside the mixing chamber

![]()

Mixing Chamber

Entirely manufactured from heavy-duty stainless steel with low-roughness surface finish:

- No product contamination

- High service life

- Low residue and easy cleaning

![]()

![]()

On-board Equipment

All on-board equipment is fitted in closed compartments and protected from accidental impacts and/or tampering

![]()

Scraper Blades

Manufactured from heat-resistant material, they reduce the clearance between mixing tool and chamber:

- Minimum residue and reduced cleaning time

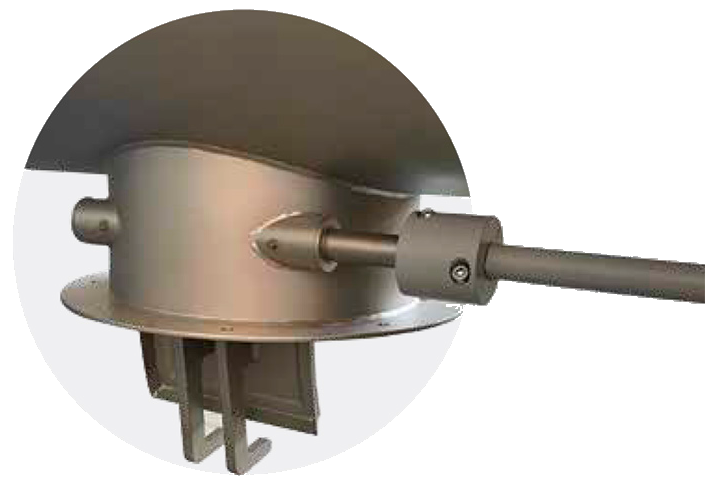

Sampling Device

Possible to check the quality of the product by taking a sample easily and at any time during operation:

- Pre-equipment as standard allows retrofitting at any time

- Reduced sampling time

- Increased operator safety

![]()

![]()

Cooling Jacket

mixron MCP is equipped with multiple cooling jackets with operating pressure of up to 3 bar:

- Increased heat exchange efficiency

- Reduced cooling time

![]()

![]()

Mixing Tools

Ensure homogeneous mixing and effective distribution of the material on the cooling surfaces.

Special head tools are supplied as standard, enabling the reduction of material build-up in the end zones of the mixing chamber.

![]()

![]()

![]()

All rights reserved – Mixron srl – Via Brigata Ebraica, 50 – 48123 – Ravenna (RA) – ITALY – P.IVA 03456680366